Box Build Assembly

New Product Introduction

Prototype Service

Design For Manufacturing

Supply Chain Solutions

PCB Assembly

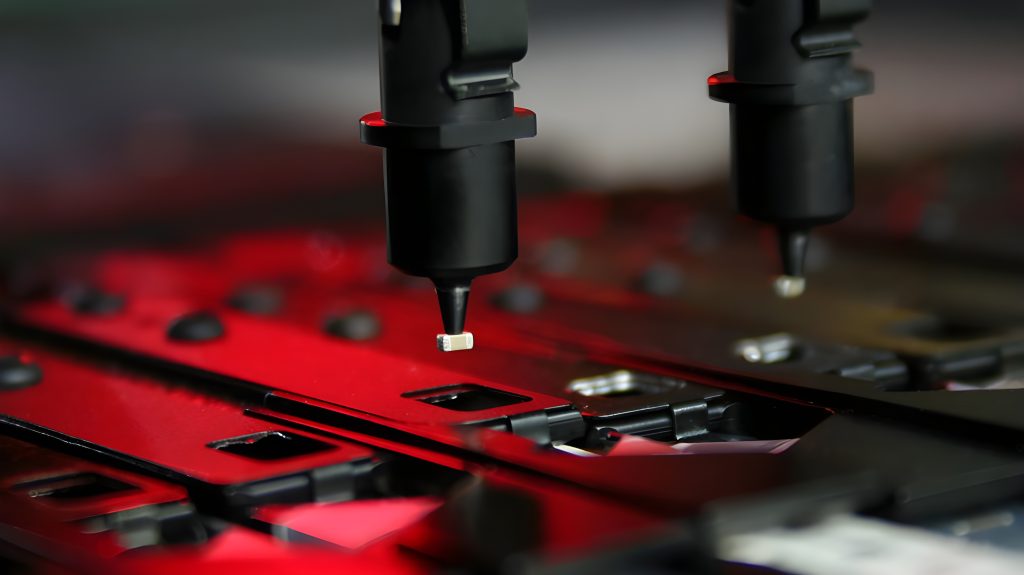

At CG Global, our PCBA process is designed to ensure top-tier quality with advanced manufacturing capabilities. We specialize in multi-layer PCBA through our Surface Mount Technology (SMT) process. Our facilities allow us to produce high-quality PCBA with precision and efficiency.

Following the SMT process, our manual insert lines equipped with selective and wave soldering machines. These lines facilitate the mounting of through-hole components, ensuring meticulous assembly and a seamless transition from SMT to through-hole soldering.

Our commitment to utilizing cutting-edge manufacturing facilities guarantees the utmost accuracy and reliability in every step of the PCBA process, meeting the highest industry standards.

PCB Assembly

At CG Global, our PCBA process is designed to ensure top-tier quality with advanced manufacturing capabilities. We specialize in multi-layer PCBA through our Surface Mount Technology (SMT) process. Our facilities allow us to produce high-quality PCBA with precision and efficiency.

Following the SMT process, our manual insert lines equipped with selective and wave soldering machines. These lines facilitate the mounting of through-hole components, ensuring meticulous assembly and a seamless transition from SMT to through-hole soldering.

Our commitment to utilizing cutting-edge manufacturing facilities guarantees the utmost accuracy and reliability in every step of the PCBA process, meeting the highest industry standards.

Types of PCB

Multilayer PCB

Double sided PCBs

Aluminium PCB

Polyimide

High Tg PCB

Rigid

FR4

Teflon

Copper

Flex

OSP PCB

Flexible PCB

Single sided PCBs

High frequency PCB

HDI

Copper clad laminate

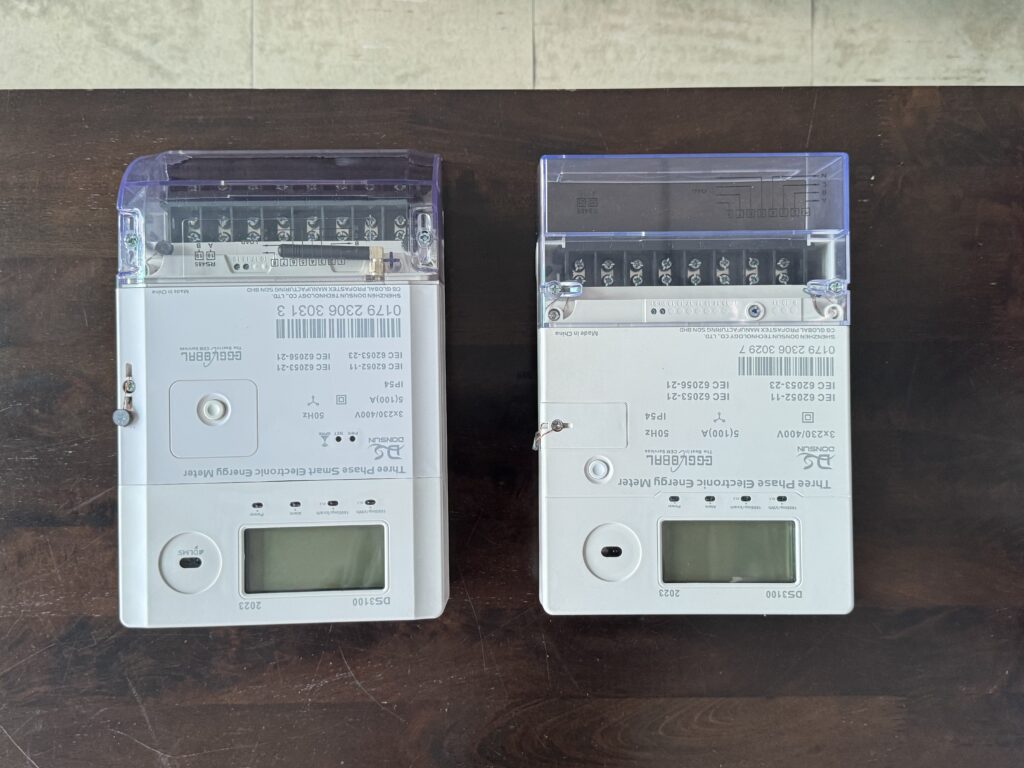

Box Build Assembly

Building upon our expertise in PCBA, CG Global extends its services to encompass box build assembly and full product assembly for OEMs across diverse industries. Our final assemblies facilities includes complete final assembly lines staffed by experienced labour, ensuring meticulous attention to detail and a commitment to delivering superior products.

From integrating PCBAs into enclosures to providing a full-scale product assembly, CG Global guarantees exceptional quality and functionality. Our assurance of good products stems from our dedication to utilizing advanced technology, efficient processes, and a skilled workforce, enabling us to meet demands of our clients across various industries.

Box Build Assembly

Building upon our expertise in PCBA, CG Global extends its services to encompass box build assembly and full product assembly for OEMs across diverse industries. Our final assemblies facilities includes complete final assembly lines staffed by experienced labour, ensuring meticulous attention to detail and a commitment to delivering superior products.

From integrating PCBAs into enclosures to providing a full-scale product assembly, CG Global guarantees exceptional quality and functionality. Our assurance of good products stems from our dedication to utilizing advanced technology, efficient processes, and a skilled workforce, enabling us to meet demands of our clients across various industries.

CG Global's Final Assembly Process

Sub Assembly

Mechanical Assembly

Final Assembly

Software loading and

product configuration

Testing

Functional Check

Visual & Manual

Inspection

Packing

Prototype Service

CG Global offers rapid PCBA prototyping services for quick-turn PCBA at high quality and competitive cost. We”re fully compliant with ISO9001:2015 and ISO13485:2016 quality management systems. We also have an in-house quality control department to verify that all work meets each regulation depicted by the high standards.

It all starts with document package. Once received, our design engineers and supply chain experts assess and evaluate your design and Bill of Materials (BOM) to ensure Design for Manufacturability (DFM), parts availability, and scalability to full production.

Your product then moves to the NPI line for prototyping. Prototyping ensures your product can be assembled as instructed without defects or inefficiencies. If any exceptions are identified, we work closely with you to resolve those issues. We can then repeat the prototyping process to get your product to its final design. Our engineering teams can update your documentation, as well, so you know your design, assembly instructions, and BOM remain current.

PCBA design moves from proof of concept to prototype in just one to two weeks from receipt of materials.

Prototype Service

CG Global offers rapid PCBA prototyping services for quick-turn PCBA at high quality and competitive cost. We”re fully compliant with ISO9001:2015 and ISO13485:2016 quality management systems. We also have an in-house quality control department to verify that all work meets each regulation depicted by the high standards.

It all starts with document package. Once received, our design engineers and supply chain experts assess and evaluate your design and Bill of Materials (BOM) to ensure Design for Manufacturability (DFM), parts availability, and scalability to full production.

Your product then moves to the NPI line for prototyping. Prototyping ensures your product can be assembled as instructed without defects or inefficiencies. If any exceptions are identified, we work closely with you to resolve those issues. We can then repeat the prototyping process to get your product to its final design. Our engineering teams can update your documentation, as well, so you know your design, assembly instructions, and BOM remain current.

PCBA design moves from proof of concept to prototype in just one to two weeks from receipt of materials.

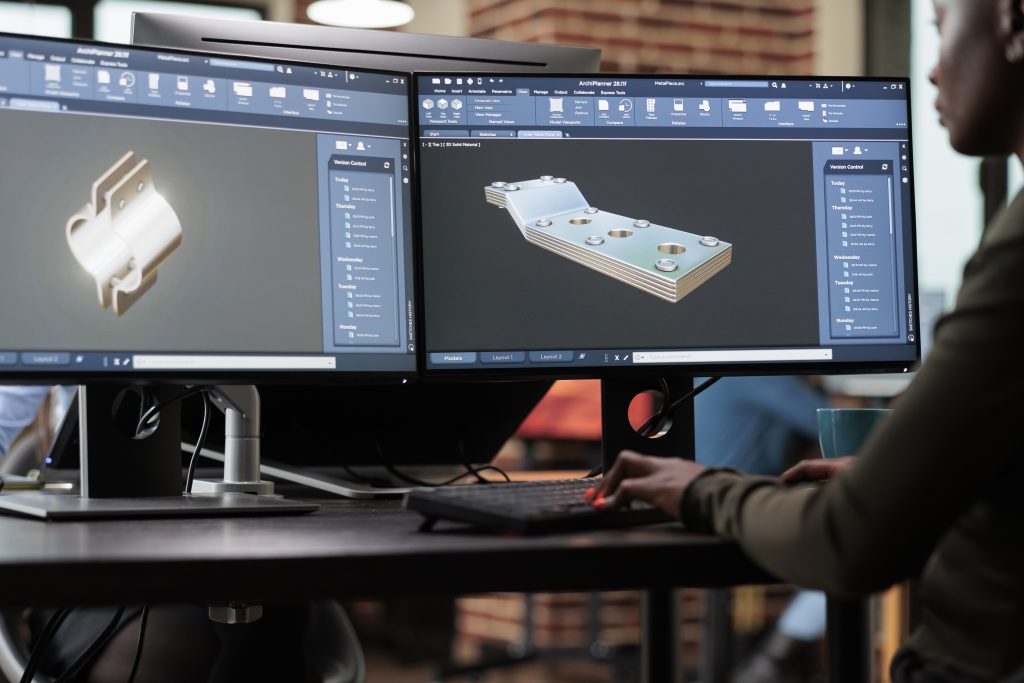

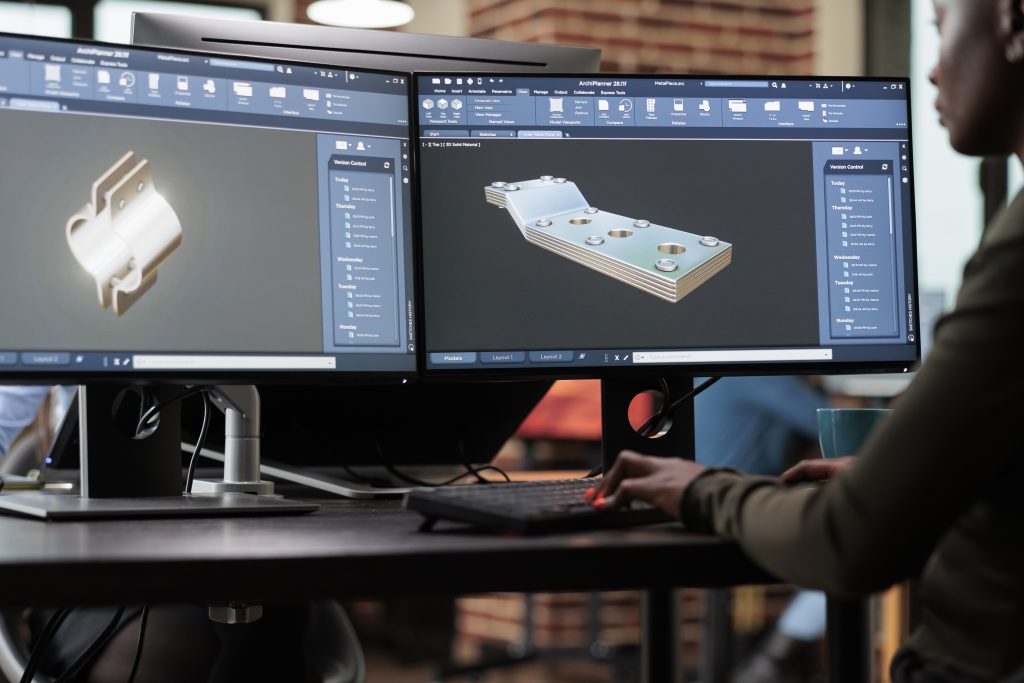

NPI and Design for Manufacturing

CG Global mission is to bring out new products in quick timelines to stay ahead. Building a successful new product involves a well-established printed circuit board assembly (PCBA) manufacturing process that focuses on continuous improvement with structured process known as New Product Introduction (NPI).CG Global collaborate with customer technical teams from the early design stages to ensure reduced cost and quick product launches.

NPI and Design for Manufacturing

CG Global mission is to bring out new products in quick timelines to stay ahead. Building a successful new product involves a well-established printed circuit board assembly (PCBA) manufacturing process that focuses on continuous improvement with structured process known as New Product Introduction (NPI).CG Global collaborate with customer technical teams from the early design stages to ensure reduced cost and quick product launches.

NPI Process

Manufacturing yield is accelerated by adopting Design for Excellence (DfX) during PCB development. Following the design guidelines for better assembly (DFA), testing (DFT), manufacturability (DFM), and reliability (DFR) reduces possible defects and improves product quality.

The NPI process includes careful consideration of product requirements starting from feature analysis, component sourcing, and early prediction of possible assembly or manufacturing issues. This reduces the overall product development cost.

NPI focuses on the product-to-market timeline through diligent follow-up of the schedules and networking with multiple vendors for component sourcing. This leads to better return on investment (ROI).

A detailed NPI process results in reliable products and higher customer satisfaction.

Several simulations and analysis tools are used in the NPI process for guided technology decisions. This enhances product quality significantly and reduces re-spins.

An organized NPI process emphasizes strong product lifecycle management by optimizing the supply chain with the obsolescence management of components and other materials. Seamless switching to new suppliers and reduced inventory wastage improves the ROI and reduces the overall manufacturing cost.